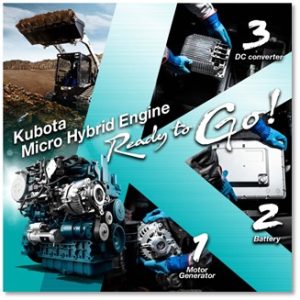

3, 2, 1… Micro-Hybrid Engine is Ready to Go!

Kubota Engine America’s V3307 Micro-Hybrid Engine provides power assistance during peak performance, using electric power to compensate for high loads instantaneously. For some applications, high load is required for only a fraction of the total work time. The engine’s 10-kW electric motor-assist function allows customers to match those high load demands and select an engine with an output power tailored to the low and medium load regions of frequent use.

In addition, machinery already equipped with a Kubota engine can leverage this Micro-Hybrid technology by installing three main components. This allows customers to enhance the added value of their existing applications with a minimal development cost.

What’s Included in the Micro-Hybrid Engine and how is it Useful?

Kubota’s Micro-Hybrid Engine stresses its minimal implementation, making the engine a simple, easy-to-install system. The engine has a straightforward design with three main components: a DC converter, a lithium-ion battery and a motor generator attached to the existing engine model.

In addition, the Hybrid system is controlled by the engine control unit (ECU), not big signals from the vehicle. This is made possible by rewriting the software in the existing ECU, only available to Kubota engines. No additional ECU is required for Hybrid control.

High Torque with Quick Response

The engine is equipped with a 48-V motor generator, providing high torque with quick response – boosting overall work efficiency. At low speeds, the motor provides up to 70 N⋅m of torque assistance. Designed for applications that demand an immediate response to instantaneous peak overloads within the typical machine duty cycle, the power assist Micro-Hybrid system supports the engine by delivering an additional electrical power boost of up to 10kW. The instant available torque offers an efficiency boost at the most crucial time, while recuperating and recharging its battery pack when not initiated. These innovations push the boundaries in areas of fuel efficiency, power density and adaptability.

Lower Running Costs

By choosing Kubota’s Micro-Hybrid Engine technology, it will fit compactly in your mounting space, with no selective catalytic reduction (SCR) required for diesel engines with output of

56kW or more. Eliminating the need for SCR saves on time needed to top up diesel exhaust fluid (DEF). It saves maintenance work and eliminates the running cost of DEF.

In addition, the motor-assist function can also be expected to help reduce fuel consumption.

Why Would I Choose This Engine Over Competitors?

Choosing the Kubota Micro-Hybrid Engine, over other competing engines, provides the opportunity for quicker motor response and stronger work efficiency, with minimal effort to install! Based on our experience, we’re confident that the Micro-Hybrid system will offer greater opportunities for equipment manufacturers to harness advances in product design flexibility, optimization, efficiencies and total cost of ownership derived from down-sizing, while maintaining the overall machine performance and productivity.

The Kubota Micro-Hybrid Engine complies with EPA/CARB Tier 4 and State V emission regulations. Contact us for more information about this power source!